Tencuiala fonoabsorbanta si acustica din pluta NZEBSHOP Acoustix Plus

laster, do not

compress

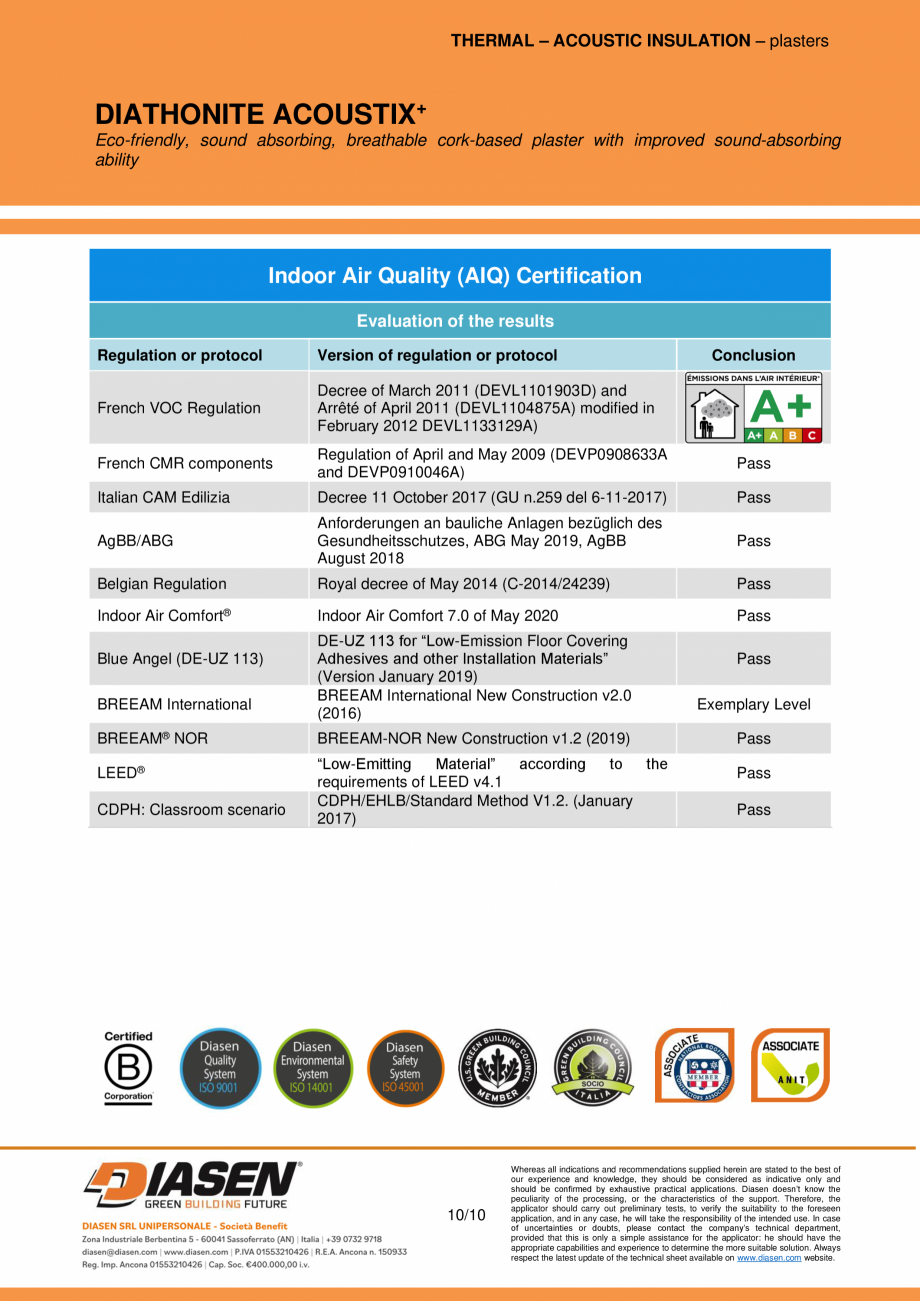

Diathonite

Acoustix+

to

preserve the porosity of the product. Use

an H-shape or a knife to obtain a smooth

surface, with fluid horizontal and vertical

movements.

1.

2.

3.

4.

5.

6.

7.

Application by plastering machine

Diathonite Acoustix+ can be applied with

plastering machines for lightened premixed

3/10

It is essential to wet the support,

especially in summer and in case of walls

directly exposed to the sun. In case the

surfaces were primed beforehand, it is

not necessary to wet the support.

Load the contents of the bags inside the

hopper and adjust the flow meter of the

machine. Correct the regulation of the

water through the flow meter, starting

from a high dosage and decreasing the

water flow until the consistency is

suitable for the perfect grip.

Spray the product downside up, thus

applying a first layer of Diathonite

Acoustix+ as a rough coat with maximum

thickness of about 1,5 cm (0.59 inches).

Spray Diathonite Acoustix+ with few

interruptions. I

... ascunde

Alte documentatii ale aceleasi game Vezi toate

Fisa tehnica

8 p | EN

Diathonite Thermactive .037

Fisa tehnica

7 p | EN

Deumix